Exterior House Sheathing A Comprehensive Guide

Exterior house sheathing forms the crucial protective layer beneath your home’s siding, significantly impacting its durability, energy efficiency, and overall lifespan. Understanding the different sheathing materials – plywood, OSB, fiber cement, and composite wood – and their respective properties is key to making informed decisions during construction or renovation. This guide will walk you through the selection, installation, and maintenance of exterior house sheathing, covering everything from building codes to moisture management.

We’ll delve into the specifics of installation methods, highlighting best practices for proper alignment and fastening to ensure a robust and long-lasting exterior wall system. We’ll also explore how different sheathing materials interact with moisture and impact your home’s energy efficiency and fire resistance. By the end, you’ll have a solid grasp of how to choose and install the right sheathing for your project, resulting in a stronger, more energy-efficient, and safer home.

Types of Exterior House Sheathing

Source: gkseries.com

Choosing the right exterior sheathing is a crucial step in building or renovating a house. It provides structural support, protects against the elements, and forms the base for your siding. Several materials offer varying levels of performance, cost, and aesthetics. Let’s explore some of the most common options.

Plywood Sheathing

Plywood sheathing is a popular choice, constructed from thin layers of wood veneer glued and pressed together with the grain of adjacent layers oriented at right angles. This cross-grain construction provides exceptional strength and stability. Plywood is available in various grades, with higher grades offering better surface quality and fewer knots. Advantages include its strength, relatively easy workability, and readily available sizes. However, plywood can be susceptible to moisture damage, leading to swelling or rot if not properly protected. It also tends to be more expensive than OSB.

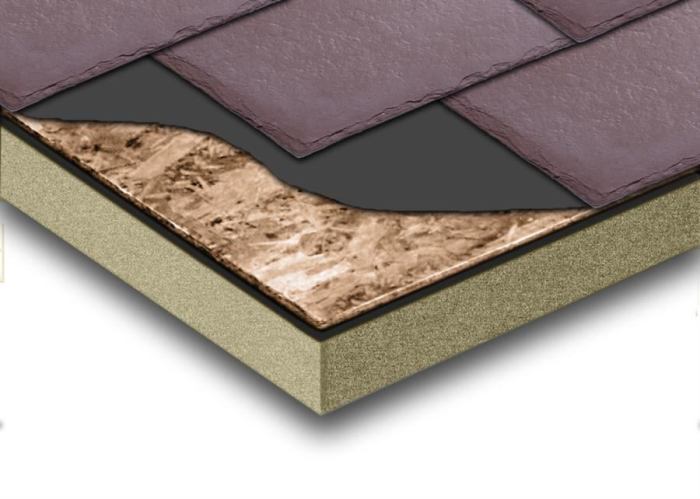

Oriented Strand Board (OSB) Sheathing

OSB sheathing is made from wood strands or flakes bonded together with resin. These strands are oriented in layers, similar to plywood, to maximize strength. OSB is generally less expensive than plywood and offers comparable structural performance in many applications. It’s also less prone to splitting than plywood. However, OSB is generally less water-resistant than plywood and may be more susceptible to damage from moisture, especially at the edges. Its surface is also typically less smooth than plywood.

Fiber Cement Sheathing

Fiber cement sheathing is a non-combustible material made from a mixture of cement, cellulose fibers, and other additives. This creates a durable, fire-resistant, and moisture-resistant sheathing option. Fiber cement is highly resistant to rot, insects, and weathering, making it a long-lasting choice. However, it’s more expensive than plywood or OSB and can be more challenging to cut and install due to its density and hardness.

Composite Wood Sheathing

Composite wood sheathing combines wood fibers with plastic polymers to create a material that offers a balance of strength, durability, and moisture resistance. These products often boast improved dimensional stability compared to traditional wood sheathing, meaning less expansion and contraction with changes in humidity. While offering some advantages, composite wood sheathing is typically more expensive than plywood or OSB and may have less widespread availability.

Sheathing Material Comparison

Here’s a table comparing the cost, durability, and insulation properties of the sheathing types discussed. Note that these values are relative and can vary based on specific product specifications and regional pricing.

| Sheathing Type | Cost (Relative) | Durability (Relative) | Insulation (R-Value) |

|---|---|---|---|

| Plywood | Medium-High | Medium-High | 0.7-1.0 per inch |

| OSB | Low-Medium | Medium | 0.7-1.0 per inch |

| Fiber Cement | High | High | 0.2-0.4 per inch |

| Composite Wood | Medium-High | High | Varies by product |

Plywood vs. OSB: Structural Differences

Imagine two sheets of sheathing, one plywood and one OSB. The plywood sheet shows distinct layers of thin wood veneer, each running perpendicular to the adjacent layer. This creates a strong, interwoven structure. In contrast, the OSB sheet displays larger, more visible wood strands or flakes, bonded together in layers. While the layers also run perpendicularly for strength, the overall appearance is less uniform and the individual strands are more readily apparent. The plywood’s finer construction gives it a smoother surface, while the OSB’s larger flakes create a somewhat rougher texture. Both achieve structural strength through layered construction, but the visible differences highlight their distinct manufacturing processes.

Sheathing Installation Methods

Source: dreamstime.com

Installing exterior house sheathing is a crucial step in building a durable and weather-resistant home. Proper installation ensures the structural integrity of your walls and protects your home from the elements. This process involves careful planning, precise measurements, and the use of appropriate tools and techniques. Ignoring best practices can lead to issues like gaps, uneven surfaces, and potential water damage down the line.

Getting started requires a solid understanding of the chosen sheathing material, the local building codes, and the specific conditions of your project. Remember that weather conditions can significantly impact the installation process and the longevity of the sheathing.

Fastening Techniques

Proper fastening is paramount for secure sheathing installation. The type and spacing of fasteners depend on the sheathing material (OSB, plywood, etc.), the wall framing, and local building codes. Generally, you’ll use galvanized nails or screws designed for exterior applications. For example, using 8D nails spaced 6 inches apart along the edges and 8 inches apart in the field for OSB sheathing is a common practice, but always consult the manufacturer’s recommendations and local building codes for precise specifications. Driving fasteners straight and flush with the sheathing surface is crucial to prevent damage and ensure proper water shedding. Overdriving can split the sheathing, while underdriving can compromise its strength. In areas prone to high winds or seismic activity, additional fasteners may be required for enhanced structural support.

Alignment and Gap Minimization

Maintaining consistent alignment and minimizing gaps between sheathing panels is vital for a smooth, watertight exterior wall. Start by carefully aligning the first panel with a plumb line and level. Subsequent panels should be butted tightly against each other, ensuring straight lines and consistent spacing. Use shims to correct any misalignment and create a level surface. Avoid excessive gaps, as they can allow water penetration and compromise the building’s insulation. Overlapping panels according to the manufacturer’s specifications are crucial, usually involving a minimum overlap of several inches to create a strong, sealed joint. For example, staggered joints (offsetting the seams of adjacent panels) will increase the strength and water resistance of the sheathing.

Tools and Materials

Before beginning installation, gather all necessary tools and materials. This will streamline the process and prevent delays.

- Exterior-grade sheathing (OSB, plywood, etc.)

- Galvanized nails or screws (appropriate size and length)

- Measuring tape

- Level

- Plumb bob

- Circular saw or hand saw

- Hammer or impact driver

- Safety glasses

- Work gloves

- Shims

- Caulk (for sealing gaps)

Remember to always prioritize safety. Wear appropriate personal protective equipment (PPE), including safety glasses and work gloves, throughout the installation process. Proper planning and execution will result in a well-installed sheathing system, contributing to a strong, durable, and weather-resistant home.

Sheathing and Building Codes

Source: shutterstock.com

Exterior house sheathing isn’t just about protecting your home from the elements; it’s a crucial structural component governed by strict building codes. These codes vary by region and even by the specific type of construction project, ensuring the safety and stability of your building. Understanding these regulations is vital for homeowners and builders alike to avoid costly mistakes and potential safety hazards.

Sheathing requirements are detailed in local, state, and sometimes even national building codes. These codes often reference model codes, such as the International Building Code (IBC) and the International Residential Code (IRC), which provide a baseline for many jurisdictions. However, local amendments and interpretations are common, making it essential to check with your local building department for the specific requirements in your area.

Regional Variations in Building Codes for Sheathing, ExteriorHouse Sheathingg

Building codes related to sheathing can differ significantly depending on geographic location. Coastal areas, for example, might have stricter requirements for wind resistance, mandating the use of thicker sheathing or specialized fasteners. Areas prone to seismic activity may have requirements for shear wall design, impacting the type and installation method of the sheathing. Similarly, regions with heavy snow loads might require more robust sheathing to withstand the added weight. For instance, a home built in hurricane-prone Florida will have vastly different sheathing requirements compared to a home built in a relatively calm inland region of Colorado. Always consult the relevant code for your specific location.

Sheathing Requirements in Different Construction Types

Residential construction typically adheres to the IRC, which provides detailed specifications for sheathing thickness, type, and installation. Commercial construction, however, often falls under the IBC, which may have more stringent requirements due to the increased scale and complexity of the buildings. Commercial projects might require engineered sheathing solutions, detailed structural calculations, and rigorous inspections to ensure the building’s structural integrity. For example, a high-rise apartment building would necessitate far more robust sheathing and stricter installation practices compared to a single-family home.

Consequences of Non-Compliance with Sheathing Building Codes

Failure to comply with building codes related to sheathing can lead to several serious consequences. These can include:

- Structural Failure: Inadequate sheathing can compromise the structural integrity of the building, potentially leading to collapse or significant damage during extreme weather events.

- Building Permit Denial: Projects that don’t meet code requirements may not receive building permits, halting construction until the necessary changes are made.

- Financial Penalties: Building inspectors may impose fines for code violations, adding unexpected costs to the project.

- Insurance Issues: Insurance companies may refuse to cover damages caused by inadequate sheathing, leaving homeowners liable for significant repair costs.

- Legal Liability: In severe cases, builders or homeowners could face legal action if structural failures result in injury or property damage.

For example, a house built with improperly installed sheathing that fails during a hurricane could result in significant financial losses for the homeowner and potential legal action against the builder. This underscores the critical importance of adhering to all applicable building codes.

Sheathing and Moisture Management

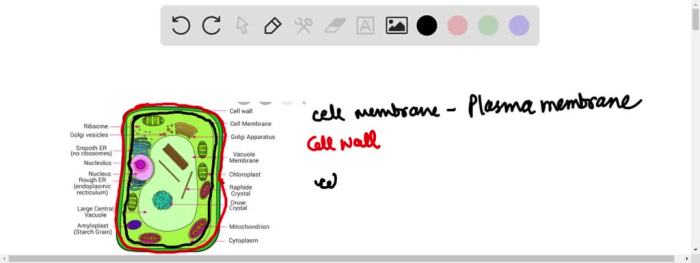

Source: numerade.com

Proper sheathing installation is crucial not only for structural integrity but also for effective moisture management, preventing costly and damaging water intrusion. Exterior sheathing acts as the first line of defense against the elements, but its effectiveness is significantly enhanced by the use of additional moisture barriers and careful attention to installation techniques. Ignoring moisture control can lead to rot, mold growth, and structural weakening, impacting the longevity and livability of your home.

Sheathing materials, while providing structural support, possess varying degrees of water resistance. Understanding these differences and implementing appropriate moisture control strategies is paramount to protecting your investment. The interaction between sheathing and moisture barriers like house wrap creates a system designed to divert water away from the building’s core, preventing moisture from penetrating the walls and causing damage.

House Wrap and Moisture Barriers

House wrap, a permeable membrane, is commonly installed over sheathing. It allows water vapor to escape from the interior while preventing liquid water from entering. This is crucial because even the most water-resistant sheathing isn’t completely waterproof. Different types of house wraps exist, offering varying levels of breathability and water resistance. For instance, some are designed to be more effective in high-humidity climates, while others prioritize durability and tear resistance. Proper installation, ensuring overlaps and sealing around penetrations, is critical for optimal performance. Failure to correctly install house wrap can negate its benefits, leading to moisture intrusion. Consider using breathable house wrap with a proper overlap (typically 6 inches) and taping all seams. This creates a continuous barrier that effectively manages moisture.

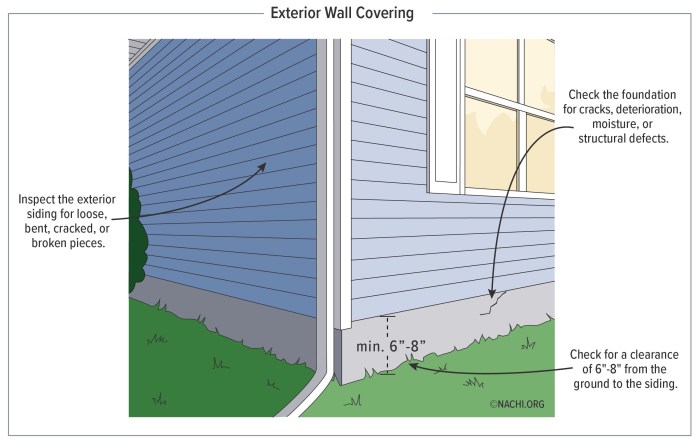

Sheathing Installation and Moisture Prevention

Proper sheathing installation directly impacts moisture control. Careful attention to details like overlapping sheathing panels, sealing gaps and seams, and ensuring proper flashing around windows and doors are essential. Improper installation can create pathways for water to penetrate, leading to problems like water damage and mold growth. For example, leaving gaps between sheathing panels can allow water to penetrate directly into the wall cavity. Similarly, inadequate flashing around windows and doors can lead to water accumulation and damage. Consistent, proper nailing is also critical to prevent gaps that allow water to enter.

Moisture Handling Characteristics of Different Sheathing Materials

Different sheathing materials have different inherent capacities to handle moisture. Oriented Strand Board (OSB) is commonly used and relatively resistant to moisture, but prolonged exposure can lead to swelling and degradation. Plywood sheathing, while also relatively moisture resistant, also shows similar vulnerability to prolonged exposure. In contrast, some engineered wood sheathing products boast improved moisture resistance, often incorporating additives or special treatments to enhance their durability in wet conditions. However, even these advanced materials benefit from the protection of a properly installed house wrap to extend their lifespan and maintain the structural integrity of the wall assembly. For instance, a study conducted by the Forest Products Laboratory showed that OSB sheathing exposed to prolonged moisture experienced a significant reduction in its structural strength, highlighting the importance of effective moisture management strategies.

Sheathing and Energy Efficiency

Source: seconarchitect.com

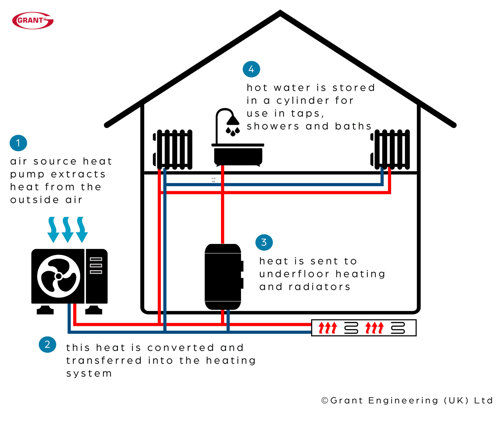

Your home’s sheathing plays a surprisingly significant role in its overall energy efficiency. The type of sheathing you choose, and how well it’s installed, directly impacts how well your house retains heat in winter and stays cool in summer. This means lower energy bills and a more comfortable living environment.

The primary way sheathing affects energy efficiency is through its thermal resistance, or R-value. A higher R-value indicates better insulation, meaning less heat transfer through the sheathing. Proper installation techniques are equally crucial; gaps and air leaks negate the benefits of even the highest-R-value material.

R-Values of Common Sheathing Materials

The R-value of sheathing varies depending on the material and its thickness. Understanding these differences is key to making informed choices for your climate.

| Sheathing Material | Thickness (inches) | Approximate R-Value |

|---|---|---|

| Oriented Strand Board (OSB) | 0.5 | 0.63 |

| Plywood | 0.5 | 0.63 |

| Foam Sheathing (Polyisocyanurate – Polyiso) | 1 | 7-8 |

| Foam Sheathing (Extruded Polystyrene – XPS) | 1 | 5 |

Note: R-values can vary slightly depending on the manufacturer and specific product. Always check the manufacturer’s specifications for accurate data.

Sheathing and Thermal Performance in Different Climates

Choosing the right sheathing is crucial for optimizing energy performance in varying climates.

In cold climates, maximizing insulation is paramount. Homes in regions with harsh winters benefit significantly from using high-R-value sheathing like foam board sheathing (polyiso or XPS), often installed in conjunction with traditional OSB or plywood sheathing. For example, a home in Minnesota might utilize 1-inch polyiso sheathing for its superior insulating properties, reducing heat loss during frigid temperatures. This reduces reliance on heating systems and subsequently lowers energy bills.

Conversely, in hot climates, the focus shifts to minimizing heat gain. While high-R-value sheathing still provides benefits by reducing heat transfer from the exterior, careful consideration should be given to the material’s reflectivity. Some foam boards offer reflective surfaces that bounce sunlight away from the house, reducing the amount of heat absorbed by the building envelope. A home in Arizona, for instance, could benefit from using reflective foam sheathing to minimize solar heat gain during the summer months. This strategy reduces the workload on cooling systems, leading to energy savings.

Proper installation is crucial regardless of climate. Air sealing around windows, doors, and other penetrations is just as important as the sheathing itself.

Sheathing and Fire Resistance: Exterior House Sheathing

Source: dreamstime.com

Choosing the right house sheathing isn’t just about structural integrity and weather protection; fire resistance is a critical factor impacting the safety and longevity of your home. Different sheathing materials offer varying levels of protection against fire spread, significantly influencing how a building performs during a fire event. Understanding these differences is crucial for responsible construction.

Different sheathing materials possess different fire-resistant properties. For instance, plywood sheathing, while structurally sound, is combustible and will burn if exposed to sufficient heat. However, certain treated plywood options offer improved fire resistance. Cement board sheathing, on the other hand, is non-combustible, providing a significant advantage in fire protection. Other options like oriented strand board (OSB) have similar flammability characteristics to plywood. The specific fire resistance also depends on the thickness and density of the sheathing. Thicker sheathing generally offers better fire protection.

Fire-Rated Sheathing and Building Safety

The use of fire-rated sheathing directly impacts building safety by slowing the spread of fire. This crucial time delay allows for safer evacuations and provides firefighters with a greater opportunity to contain the blaze, minimizing property damage and protecting lives. Fire-rated sheathing can help compartmentalize a fire, preventing it from rapidly spreading to other areas of the house. This is especially important in multi-family dwellings or buildings with complex layouts. Codes often require fire-rated sheathing in certain areas, such as around fireplaces or near fire-rated walls.

Factors to Consider When Choosing Fire-Resistant Sheathing

Choosing the right fire-resistant sheathing involves weighing several key factors.

The following points should be considered when selecting fire-resistant sheathing for your project:

- Local Building Codes: Always check local building codes and fire regulations. These codes often specify minimum fire resistance requirements for sheathing in different parts of the structure.

- Budget: Fire-resistant sheathing, particularly non-combustible options, can be more expensive than standard plywood or OSB. Balancing cost with safety is important.

- Climate: The climate in your region can influence the choice of sheathing. Some fire-resistant materials may not be as suitable for humid or wet climates as others.

- Specific Application: The location of the sheathing within the building structure dictates the level of fire resistance needed. Areas near fireplaces or other potential ignition sources typically require higher fire ratings.

- Installation Method: The installation method can affect the overall fire performance of the sheathing. Proper installation is critical to ensure the intended level of fire protection.

Common Sheathing Problems and Solutions

Source: monrovia.com

Even with careful planning and execution, problems can arise during exterior sheathing installation. Understanding these common issues and their solutions is crucial for ensuring a durable and energy-efficient building envelope. Addressing problems promptly prevents more extensive and costly repairs later.

Improper installation can lead to a variety of issues, ranging from minor cosmetic flaws to significant structural weaknesses. These problems often stem from factors like incorrect fastening, inadequate moisture protection, or the use of damaged materials. Identifying the root cause is key to implementing the right solution.

Improper Fastening

Using the wrong type of nails or screws, or failing to properly space and drive them, can significantly weaken the sheathing’s structural integrity. Under-driven fasteners can pull out, creating gaps and compromising the building’s resistance to wind and water. Over-driven fasteners can damage the sheathing material itself. The correct fastener type, length, and spacing are determined by the sheathing material, building codes, and local climate conditions. For example, using galvanized nails in coastal areas is essential to resist corrosion.

Gaps and Openings in Sheathing

Gaps between sheathing panels allow moisture intrusion, compromising the building’s insulation and leading to mold growth and structural damage. These gaps can result from improper planning, poor cutting techniques, or failure to account for expansion and contraction of the material. Careful measurement and precise cutting are vital to minimize gaps. Using appropriate sealants to fill minor gaps is also a necessary preventative measure.

Moisture Damage

Exposure to excessive moisture can cause sheathing to swell, rot, or warp, significantly reducing its structural strength and lifespan. This is especially problematic in areas with high humidity or frequent rainfall. Proper flashing, drainage systems, and the use of moisture-resistant sheathing are crucial to prevent these problems. Early detection and prompt repair of any water damage are essential to prevent further deterioration.

Damaged Sheathing

Using damaged or defective sheathing materials can lead to a multitude of problems, from compromised structural integrity to reduced energy efficiency. Inspecting all sheathing materials before installation is critical to avoid these issues. Damaged or defective panels should be immediately replaced to ensure the structural integrity of the entire wall system.

Common Sheathing Issues, Causes, and Solutions

| Issue | Cause | Solution | Prevention |

|---|---|---|---|

| Loose or Pulled Fasteners | Improper fastening, using incorrect fasteners, or impact damage. | Remove loose fasteners and replace them with correctly sized and driven fasteners. Consider adding additional fasteners for reinforcement. | Use the correct fastener type and length; ensure proper spacing and driving depth. |

| Gaps between Sheathing Panels | Improper cutting, expansion, and contraction of materials, or inadequate planning. | Fill gaps with appropriate sealant or backer rod and sealant. For large gaps, replace affected panels. | Careful measurement and cutting; use expansion joints where necessary. |

| Water Damage | Inadequate flashing, improper drainage, or exposure to prolonged moisture. | Repair damaged sheathing; ensure proper flashing and drainage; address any water intrusion sources. | Install proper flashing and drainage systems; use moisture-resistant sheathing. |

| Damaged Sheathing | Handling damage during transport or installation. | Replace damaged sheathing panels before installing further materials. | Careful handling and storage of materials. Inspect panels thoroughly before installation. |

Outcome Summary

Source: poemhunter.com

Choosing the right exterior house sheathing is a critical decision impacting your home’s structural integrity, energy efficiency, and longevity. From understanding the diverse material options and their unique properties to mastering proper installation techniques and adhering to building codes, this guide has equipped you with the knowledge to make informed choices. Remember to always prioritize proper moisture management and consider the long-term implications of your selection to ensure a safe, comfortable, and energy-efficient home for years to come. Investing time in understanding sheathing will pay off in a more durable and valuable property.