Exterior Home Sheathing A Comprehensive Guide

Exterior home sheathing is the unsung hero of your home’s exterior, silently protecting it from the elements. Understanding its various types, installation, and maintenance is key to a durable and energy-efficient home. This guide dives into the world of sheathing, exploring the different materials available, proper installation techniques, and common issues to watch out for. Get ready to become a sheathing expert!

We’ll cover everything from choosing the right material for your climate and budget to troubleshooting common problems and ensuring proper moisture management. Whether you’re a seasoned DIYer or just starting your home improvement journey, this guide will equip you with the knowledge to make informed decisions about your home’s exterior.

Types of Exterior Home Sheathing

Source: purepng.com

Choosing the right exterior sheathing is a crucial step in building or renovating a home. It impacts everything from energy efficiency and durability to the overall aesthetic appeal of your house. This section will explore the common types of sheathing available, highlighting their pros and cons to help you make an informed decision.

Exterior Sheathing Materials, Exterior home sheathing

The following table summarizes the key characteristics of common exterior home sheathing materials. Remember that the best choice will depend on your budget, climate, and personal preferences.

| Material | Advantages | Disadvantages | Cost (Relative) |

|---|---|---|---|

| Wood (e.g., plywood, OSB) | Relatively inexpensive, readily available, easy to work with, good insulation properties. | Susceptible to moisture damage, insect infestation, and fire. Requires regular maintenance (painting, staining). | Low |

| Fiber Cement | Highly durable, and resistant to moisture, fire, insects, and rot. Low maintenance. | More expensive than wood, can be brittle and prone to cracking during installation if not handled carefully, heavier than wood. | Medium-High |

| Vinyl Siding | Low maintenance, variety of colors and styles, relatively inexpensive. | Can be damaged by impact, may fade or discolor over time, not as durable as other options. | Medium |

| Metal (e.g., aluminum, steel) | Extremely durable, resistant to fire, insects, and rot. Long lifespan. | Expensive, can dent or scratch, and may be susceptible to corrosion depending on the type of metal and finish. | High |

Wood Sheathing vs. Fiber Cement Sheathing

This comparison highlights the key differences between two popular sheathing choices: wood and fiber cement. Both offer distinct advantages and disadvantages, making the right choice dependent on specific project needs and priorities.

| Attribute | Wood Sheathing | Fiber Cement Sheathing |

|---|---|---|

| Cost | Lower initial cost | Higher initial cost |

| Durability | Moderate; susceptible to moisture damage, rot, and insect infestation | High; resistant to moisture, rot, insects, and fire |

| Maintenance | Requires regular painting or staining | Low maintenance; typically requires minimal upkeep |

| Installation | Relatively easy to install | Can be more challenging to install due to weight and brittleness |

| Appearance | Natural wood look; can be stained or painted | Smooth, consistent finish; typically painted |

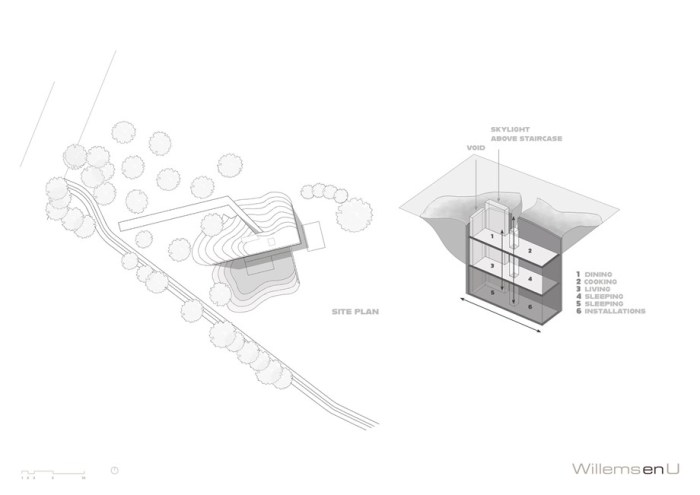

Sheathing Installation Methods

Source: f-cdn.com

Installing exterior sheathing is a crucial step in building a durable and weather-resistant home. Proper installation ensures the longevity and structural integrity of your house, protecting it from the elements and providing a solid base for your siding. Different sheathing materials require slightly different techniques, but the core principles of proper fastening, moisture management, and alignment remain consistent.

This section details the step-by-step process for installing both wood and fiber cement sheathing, highlighting key differences and best practices.

Wood Sheathing Installation

Installing wood sheathing is generally straightforward, but careful attention to detail is vital. The following steps Artikel the process for a typical residential application. Remember to always consult local building codes and manufacturer’s instructions.

- Prepare the Wall Framing: Ensure the wall framing is plumb, square, and properly braced. Address any irregularities before sheathing installation begins.

- Lay Out the First Sheet: Begin at a corner, aligning the sheathing with the framing and ensuring proper spacing for expansion. Use a level to check for plumb and square.

- Fasten the Sheathing: Use appropriate nails or screws, driving them straight and flush with the surface. Follow the manufacturer’s recommendations for spacing and penetration depth. Stagger nail patterns to distribute the load effectively.

- Install Subsequent Sheets: Continue installing sheets, overlapping edges according to building code requirements. Maintain consistent spacing and alignment throughout the process.

- Cut and Fit Around Openings: Carefully cut and fit sheathing around windows, doors, and other openings. Ensure proper support and sealing around these areas.

- Install Flashing and Sealants: Apply flashing and sealants around openings and at edges to prevent water penetration. This is crucial for preventing moisture damage.

- Inspect and Correct: Thoroughly inspect the completed sheathing for any gaps, loose fasteners, or other imperfections. Make necessary repairs before proceeding to the next stage of construction.

Fiber Cement Sheathing Installation

Fiber cement sheathing offers superior durability and moisture resistance compared to wood. However, its installation requires more attention to detail, particularly regarding fastening and moisture management.

- Prepare the Framing: Similar to wood sheathing, ensure the framing is plumb, square, and properly braced. Pay close attention to the framing’s straightness as fiber cement sheathing doesn’t flex as easily as wood.

- Fastening: Use corrosion-resistant nails or screws specifically designed for fiber cement. Pre-drilling pilot holes are often recommended to prevent cracking. Follow the manufacturer’s recommendations for fastener type, spacing, and penetration depth meticulously.

- Moisture Management: Properly flashed and sealed window and door openings are critical with fiber cement. Because fiber cement is less forgiving than wood when it comes to moisture intrusion, ensure all seams are sealed properly. Also, consider using a water-resistant barrier under the sheathing in high-moisture climates.

- Cutting and Fitting: Use a circular saw with a carbide-tipped blade specifically designed for cutting fiber cement. Wear appropriate safety gear, including eye and dust protection. Precise cuts are essential to avoid waste and ensure a tight fit.

- Inspection: Thoroughly inspect the installed sheathing for any imperfections. Fiber cement is less forgiving than wood, so it’s important to catch any problems early.

Comparison of Sheathing Installation Methods

The table below summarizes the key differences in installation methods for various sheathing types.

| Sheathing Type | Fastening Method | Moisture Management | Special Tools/Techniques |

|---|---|---|---|

| Wood | Galvanized nails or screws | Water-resistant barrier (often recommended), proper flashing and sealing around openings | Standard framing tools, nail gun (optional) |

| Fiber Cement | Corrosion-resistant nails or screws, pre-drilling often recommended | A water-resistant barrier is often recommended, as meticulous flashing and sealing, careful attention to seam sealing | Circular saw with carbide-tipped blade, appropriate safety gear (eye and dust protection), corrosion-resistant fasteners |

| Oriented Strand Board (OSB) | Galvanized nails or screws | Water-resistant barrier (often recommended), proper flashing and sealing around openings | Standard framing tools, nail gun (optional) |

| Plywood | Galvanized nails or screws | Water-resistant barrier (often recommended), proper flashing and sealing around openings | Standard framing tools, nail gun (optional) |

Sheathing and Building Codes

Source: f-cdn.com

Exterior sheathing isn’t just slapped onto a house; its installation is strictly governed by building codes to ensure structural integrity, weather resistance, and overall safety. These codes vary depending on your location – from local ordinances to state regulations and even national standards like the International Building Code (IBC). Understanding these codes is crucial for both homeowners and contractors to ensure a compliant and safe construction.

Understanding how building codes affect sheathing choices is vital for a successful project. Codes dictate minimum thicknesses, required fasteners, and acceptable materials based on factors like climate, building type, and intended use. For instance, areas prone to high winds might necessitate thicker sheathing and more robust fastening, while areas with heavy snow loads might require specific sheathing types designed to handle the increased weight. Ignoring these codes can lead to structural weaknesses, increased insurance costs, or even legal issues.

Building Code Requirements for Exterior Sheathing

The following table summarizes key building code requirements for common sheathing types. Note that these are generalized examples and specific requirements will vary significantly based on location and project specifics. Always consult your local building department for the most up-to-date and accurate information. These codes are often found in local building codes or referenced from model codes such as the IBC.

| Sheathing Type | Minimum Thickness (inches) | Fastening Pattern (inches O.C.) | Code Considerations |

|---|---|---|---|

| Oriented Strand Board (OSB) | 0.5 inch (common), but can vary depending on application and load | 6 inches O.C. (edges), 8-12 inches O.C. (field) – varies by thickness and application | Often requires specific edge sealing to resist moisture. May have specific requirements for exposure to weather during construction. |

| Plywood | 0.5 inch (common), but can vary depending on application and load | 6 inches O.C. (edges), 8-12 inches O.C. (field) – varies by thickness and application | Grade requirements (e.g., Exposure 1 for exterior use) are crucial. Specific requirements for plywood panel orientation and spacing might apply. |

| Fiber Cement Sheathing | 0.375 inch to 0.75 inch (depending on product and application) | Varies by manufacturer and application. Usually requires specific nails or screws. | Often requires specific fastening systems to achieve the required structural performance and wind resistance. |

| ZIP System Sheathing | 0.5 inch to 0.75 inch (depending on product and application) | Varies by manufacturer and application. Often uses a combination of nails and tape. | Requires adherence to manufacturer’s installation instructions for proper air and water sealing. |

Sheathing and Moisture Management: Exterior Home Sheathing

Source: banidea.com

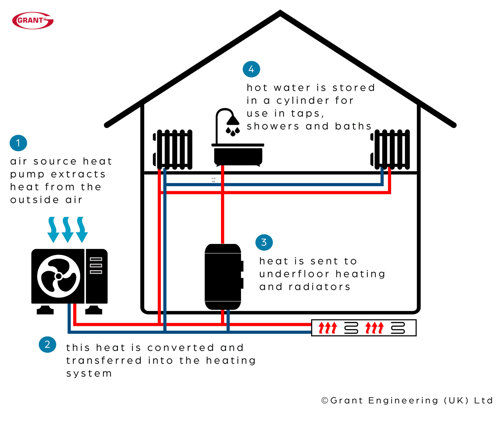

Exterior sheathing plays a crucial role in protecting your home from the elements, and a significant part of that protection involves preventing moisture from entering the building envelope. Moisture intrusion can lead to a host of problems, from mold growth and rot to structural damage and reduced energy efficiency. Understanding how sheathing interacts with moisture and employing effective management strategies is essential for a long-lasting, healthy home.

Proper moisture management is achieved through a combination of techniques designed to keep water out and allow any that does get in to escape. This is achieved through careful material selection, meticulous installation, and the implementation of effective flashing, sealing, and ventilation systems. Neglecting these strategies can lead to significant and costly problems down the line.

Flashing Techniques

Flashing acts as a barrier to prevent water from penetrating vulnerable areas of the building envelope, such as around windows, doors, and other openings. Proper flashing involves using waterproof materials, such as metal flashing or self-adhering membranes, to create a continuous barrier that redirects water away from the sheathing and the underlying structure. Critically, flashing should overlap appropriately to ensure complete coverage, and seams should be carefully sealed to prevent leakage. Failure to properly install flashing can lead to water penetrating behind the sheathing, causing significant damage.

Sealing Methods

Sealing is another vital component of moisture management. This involves using sealants, tapes and caulks to close gaps and cracks in the sheathing and around penetrations like pipes and wires. These small openings can allow water to seep into the wall cavity, leading to moisture buildup and damage. Choosing the right sealant for the specific application is crucial. For example, exterior-grade caulks are needed to withstand weathering and temperature fluctuations. Careful attention to detail during sealing is essential to prevent future water intrusion.

Ventilation Strategies

Adequate ventilation is critical for allowing moisture to escape from the wall cavity. This is typically achieved through the use of a continuous air barrier and proper soffit and ridge vents in the roof system. This allows air to circulate, carrying moisture away and preventing it from accumulating within the wall assembly. Insufficient ventilation can trap moisture, leading to mold growth, rot, and reduced energy efficiency. The importance of maintaining proper ventilation cannot be overstated; it’s a crucial aspect of a healthy and durable building envelope.

Impact of Improper Moisture Management

Imagine a cross-section of a wall. In a scenario with poor moisture management, we see water penetrating through a gap in the flashing around a window. This water then travels behind the sheathing, accumulating within the wall cavity. The sheathing itself becomes saturated, leading to swelling and eventual rot. The moisture also impacts the insulation, reducing its effectiveness and potentially leading to mold growth. Further, the water can reach the interior wall finish, causing staining and other damage. This visualization highlights the cascading effects of improper moisture management, demonstrating how a seemingly minor oversight can result in extensive and costly repairs.

Sheathing and Energy Efficiency

Source: god.cn

Choosing the right exterior sheathing significantly impacts your home’s energy efficiency and, consequently, your utility bills. Different materials offer varying levels of thermal resistance, affecting how much heat escapes in winter and how much heat enters in summer. Understanding these differences is crucial for building or renovating an energy-efficient home.

Sheathing’s thermal performance is primarily determined by its R-value, a measure of its resistance to heat flow. Higher R-values indicate better insulation and reduced energy loss. While sheathing alone won’t fully insulate your home, it forms a critical part of the overall building envelope, contributing to the overall energy performance. The interaction between sheathing R-value and the insulation installed within the wall cavity is synergistic – a high R-value sheathing enhances the effectiveness of the cavity insulation.

R-Values of Common Sheathing Materials

The R-value of sheathing varies depending on the material’s thickness and density. For example, a ½-inch thick OSB sheathing might have an R-value of around 0.6, while a thicker, denser material like foam sheathing can achieve significantly higher R-values. This table provides a general comparison, keeping in mind that actual R-values can fluctuate slightly based on the specific product and manufacturer.

| Sheathing Material | Typical Thickness | Approximate R-value per inch |

|---|---|---|

| Oriented Strand Board (OSB) | ½ inch | 0.75 – 0.9 |

| Plywood | ½ inch | 0.6 – 0.8 |

| Fiber Cement | ½ inch | 0.4 – 0.6 |

| Expanded Polystyrene (EPS) Foam | 1 inch | 3.7 – 4.2 |

| Extruded Polystyrene (XPS) Foam | 1 inch | 4.5 – 5.0 |

Impact of Sheathing Choice on Energy Consumption

Choosing the right sheathing can lead to substantial savings on energy bills. Consider these examples:

- A home using high-R-value foam sheathing might experience a 10-15% reduction in heating and cooling costs compared to a home using standard OSB sheathing, assuming similar insulation levels in the wall cavity. This is because less heat is transferred through the sheathing itself.

- In a climate with extreme temperatures, the difference in energy savings becomes even more pronounced. A house in a region with harsh winters and hot summers could see a significantly greater reduction in energy consumption by opting for higher-performing sheathing.

- The initial investment in higher R-value sheathing is often recouped over time through reduced energy costs. A simple cost-benefit analysis considering energy savings, material cost, and lifespan can justify the increased upfront investment.

Common Sheathing Issues and Repairs

Source: god.cn

Exterior home sheathing, while crucial for structural integrity and weather protection, is susceptible to various problems over time. Understanding these issues and knowing how to repair them is vital for maintaining your home’s value and longevity. Ignoring damage can lead to more extensive and costly repairs down the line, potentially impacting your home’s structural soundness and energy efficiency.

Sheathing Rot and Decay

The wood sheathing is vulnerable to rot and decay, primarily caused by prolonged exposure to moisture. This can stem from leaking roofs, faulty flashing, inadequate drainage, or even simply high humidity. Rot manifests as discoloration, softening of the wood, and a spongy texture. Severe cases can lead to structural weakness. Repair involves removing the affected sheathing, treating the surrounding area with a fungicide, and replacing the damaged sections with new, appropriately treated lumber. Always ensure proper ventilation and drainage to prevent recurrence.

Pest Damage to Sheathing

Termites, carpenter ants, and other wood-boring insects can significantly weaken sheathing. Infestations often go unnoticed until significant damage has occurred. Signs include small holes, frass (insect droppings), and hollow-sounding areas when tapped. Treatment requires professional pest control services to eliminate the infestation and repair the damaged sheathing. This might involve localized repairs or, in severe cases, the replacement of large sections. Preventive measures include using treated lumber and maintaining a dry environment around the home.

Improper Sheathing Installation

Incorrect installation is a major source of sheathing problems. This can include improper fastening, gaps between sheathing panels, or inadequate sealing around windows and doors. Improper fastening can lead to sheathing movement and failure, while gaps allow moisture penetration and energy loss. Poor sealing creates pathways for water intrusion, leading to rot and mold. Repair involves carefully assessing the extent of the problem. Loose or improperly fastened sheathing may require refastening or replacement. Gaps need to be sealed with appropriate caulk or sealant, and inadequate sealing around openings should be addressed with flashing and caulking.

Troubleshooting Sheathing Issues: A Flowchart

Imagine a flowchart. The starting point is “Sheathing Problem Identified?”. If yes, the flow proceeds to “Visible Damage (Rot, Holes, etc.)?”. If yes, the next step is “Extent of Damage?”. This would branch into “Minor (Localized Repair)” and “Major (Sheathing Replacement)”. If the answer to “Visible Damage” is no, the flow moves to “Performance Issues (Moisture, Energy Loss)”. This leads to a check for “Improper Installation?”. A “Yes” response leads to the assessment and repair of installation issues, while a “No” response might point towards underlying issues like foundation problems or roofing defects needing further investigation by a professional.

Closure

Source: god.cn

Protecting your home’s exterior is a crucial investment, and understanding exterior home sheathing is a big part of that. From the initial selection of materials to the final installation and ongoing maintenance, we’ve covered the key aspects to ensure your home remains structurally sound, energy-efficient, and aesthetically pleasing for years to come. Remember, proper installation and regular inspection are key to preventing costly repairs down the line. So, get out there and build (or improve!) with confidence!