Cement Board Structural Sheathing A Comprehensive Guide

Cement board structural sheathing offers a robust and versatile solution for various construction needs. This guide dives into its composition, applications, installation, and long-term performance, equipping you with the knowledge to confidently utilize this material in your projects. We’ll explore its advantages over traditional sheathing like plywood and OSB, addressing common installation challenges and ensuring you understand the environmental considerations and cost-effectiveness.

From understanding the different types of cement board sheathing available to mastering proper installation techniques, we’ll cover everything you need to know to successfully integrate this material into your building projects. We’ll also delve into its durability, fire resistance, and moisture resistance, helping you make informed decisions based on your specific requirements.

Definition and Composition of Cement Board Structural Sheathing

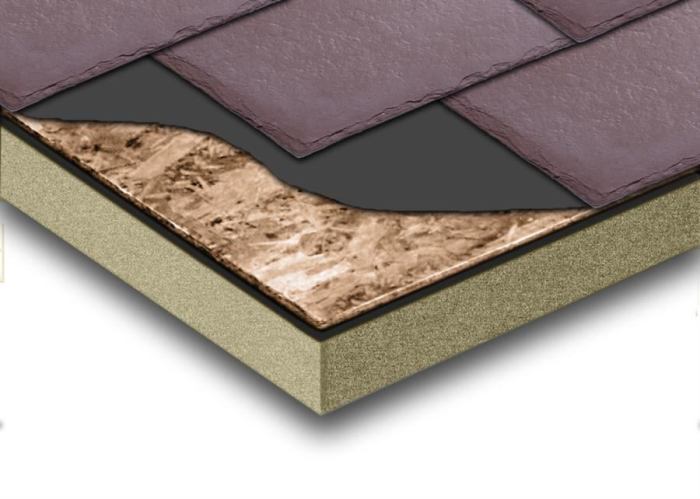

Cement board structural sheathing is a non-combustible building material used as exterior sheathing on walls and roofs. It provides a strong, durable, and moisture-resistant base for siding, stucco, or other exterior finishes. Unlike wood-based sheathing, it offers superior fire resistance and protection against water damage.

Cement board sheathing is a composite material, primarily made from Portland cement, sand, and cellulose fibers. The manufacturing process involves mixing these ingredients with water to create a slurry, which is then formed into large sheets using a press. These sheets are then cured in a controlled environment to allow the cement to fully hydrate and harden. The resulting board is dense and strong, offering excellent structural support. Some manufacturers incorporate other additives to enhance specific properties, such as improved impact resistance or water repellency.

Types of Cement Board Sheathing and Their Properties

Different types of cement board sheathing exist, each designed for specific applications and performance requirements. Variations arise from adjustments in the mix ratios of the core components and the addition of specialized modifiers. These differences affect factors like strength, water resistance, and overall cost. For instance, some boards might incorporate higher percentages of Portland cement for enhanced strength, while others may include water-repellent additives to improve durability in wet climates. Thicker boards offer superior structural support compared to thinner alternatives. Furthermore, some manufacturers offer textured surfaces designed for better adhesion with specific finishes.

Comparison of Cement Board Sheathing with Other Sheathing Materials

Cement board sheathing offers several advantages over traditional wood-based sheathing materials like plywood and OSB (oriented strand board). Plywood and OSB are susceptible to moisture damage, rot, and insect infestation, issues that cement boards largely avoid due to their inorganic composition. While plywood and OSB are generally less expensive upfront, cement board’s superior durability and longevity can lead to long-term cost savings by reducing the need for frequent replacements or repairs. However, cement board is typically heavier and more difficult to cut and install than plywood or OSB, requiring specialized tools and potentially increasing labor costs. Its higher initial cost is a factor to consider, although the extended lifespan often offsets this. The fire resistance of cement board is significantly superior to wood-based sheathing, making it a preferred choice in areas with stringent fire codes.

Applications and Uses of Cement Board Structural Sheathing

Cement board sheathing, with its robust nature and resistance to moisture and fire, finds itself a valuable component in a wide array of construction projects. Its versatility allows for use in both exterior and interior applications, significantly impacting the overall structural integrity and durability of a building. Let’s delve into its various uses and explore the advantages and disadvantages in different contexts.

Common Building Applications of Cement Board Sheathing

Cement board sheathing offers a durable and versatile solution for many construction needs. Its properties make it ideal for situations where strength, moisture resistance, and fire protection are paramount. The following list highlights some of its key applications:

- Exterior Wall Cladding: Providing a strong, weather-resistant base for siding, stucco, or brick veneer. Its strength helps resist impacts and wind uplift.

- Interior Wall Sheathing: Offering superior fire resistance and moisture protection compared to traditional wood sheathing, particularly in bathrooms and kitchens.

- Roof Sheathing: In some applications, cement board can be used as a fire-resistant underlayment for roofing materials, offering added protection.

- Fire-Rated Walls and Partitions: Its inherent fire resistance makes it a critical component in fire-rated wall assemblies, enhancing building safety.

- Backerboard for Tile Installations: A popular choice for providing a stable and water-resistant surface for tile installations in wet areas.

Advantages and Disadvantages of Cement Board Sheathing in Construction

The decision to use cement board sheathing involves weighing its benefits against potential drawbacks. The suitability depends heavily on the specific application and project requirements.

Advantages: Cement board offers superior fire resistance, moisture resistance, and impact resistance compared to traditional wood sheathing. This translates to longer-lasting structures with improved safety and reduced maintenance. Its dimensional stability minimizes warping and cracking, resulting in a smoother, more consistent finish for subsequent layers. It also provides a strong and stable base for various finishes.

Disadvantages: Cement board is heavier and more expensive than wood sheathing, potentially increasing labor costs and transportation expenses. It is also more brittle and prone to chipping and cracking during installation if not handled carefully. Cutting and fastening it requires specialized tools and techniques. Finally, its lack of flexibility can be a disadvantage in certain applications requiring conformity to curved surfaces.

Suitability of Cement Board Sheathing for Various Applications

The following table summarizes the suitability of cement board sheathing for different building applications, considering both advantages and disadvantages:

| Application | Suitability | Advantages | Disadvantages |

|---|---|---|---|

| Exterior Walls | High | Excellent weather resistance, impact resistance, and fire protection. | Higher cost and weight compared to wood sheathing. |

| Interior Walls | Medium to High | Superior fire and moisture resistance, especially in wet areas. | Higher cost and potential for chipping during installation. |

| Roofs | Medium | Provides fire protection and a stable base for roofing materials in specific applications. | Weight and brittleness can be a concern, especially in high-wind areas. Not suitable for all roofing systems. |

Installation Methods and Best Practices

Getting cement board sheathing installed correctly is crucial for a durable and weather-resistant exterior. Proper installation prevents moisture intrusion, which can lead to significant structural damage and costly repairs. This section illustrates the step-by-step process, common challenges, and best practices for a successful installation.

Step-by-Step Installation Guide

The installation process involves several key steps that, when followed carefully, ensure a long-lasting and effective sheathing system. Improper installation can compromise the building’s structural integrity and lead to premature failure of the entire wall assembly.

- Prepare the Framing: Ensure the framing is square, plumb, and properly braced. Any irregularities in the framing will transfer to the sheathing, leading to uneven surfaces and potential problems with subsequent layers.

- Cut the Cement Board: Use a wet saw with a diamond blade to cut the cement board. This prevents dust and ensures clean, accurate cuts. Dry cutting is possible but significantly increases dust and can damage the blade.

- Fastening: Use corrosion-resistant nails or screws designed specifically for cement boards. Space fasteners according to the manufacturer’s recommendations. Typically, fasteners should be placed every 6 inches along edges and 8-12 inches at the field. Overdriving fasteners can crack the board. Underdriving fastenerscompromises their holding power.

- Stagger Joints: Avoid having vertical joints align on adjacent sheets. Stagger the joints by at least 8 inches to create a stronger, more stable surface. This prevents weak points in the sheathing where moisture could potentially penetrate.

- Seal Joints and Fastener Holes: Use a high-quality, flexible sealant designed for exterior use to seal all joints and fastener holes. This prevents moisture from entering the wall assembly. Caulk should be applied neatly to avoid creating a larger gap.

- Edge Treatment: Protect exposed edges of the cement board with a suitable sealant or flashing to prevent moisture penetration. This is especially important at corners, window and door openings, and the top and bottom of the wall.

Potential Installation Challenges and Solutions

Several issues can arise during cement board installation. Addressing them proactively ensures a smooth and successful project.

- Breaking the Cement Board: Cement boards can be brittle. Use proper cutting techniques and handle it carefully to avoid breakage. If breakage occurs, replace the damaged section immediately.

- Uneven Framing: Uneven framing will lead to an uneven sheathing surface. Ensure the framing is properly squared and plumb before starting installation. Use shims to level out any irregularities.

- Improper Fastening: Incorrect fastener placement or type can lead to loose sheathing or damage to the board. Always follow the manufacturer’s recommendations for fastener type, spacing, and depth.

- Moisture Intrusion: Failing to seal joints and fastener holes properly allows moisture to penetrate, leading to damage. Use a high-quality, exterior-grade sealant and apply it generously.

Best Practices for Fastening and Sealing

Proper fastening and sealing are critical for preventing moisture damage.

Use corrosion-resistant fasteners appropriate for the cement board thickness and framing material. Always follow manufacturer’s specifications for fastener spacing and depth.

Apply a continuous bead of high-quality, flexible, exterior-grade sealant to all joints and fastener holes. Ensure complete coverage to prevent any gaps or openings.

Consider using a self-adhesive flashing tape to further enhance the sealing of joints, especially in areas prone to moisture penetration.

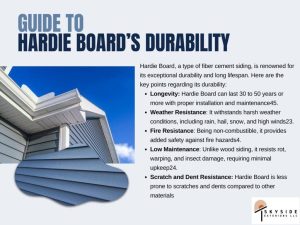

Performance Characteristics and Durability

Cement board sheathing boasts a compelling combination of strength, resilience, and longevity, making it a popular choice for various construction applications. Its performance characteristics stem directly from its composition, a blend of Portland cement, reinforcing fibers, and other additives. This results in a material that excels in fire resistance, moisture resistance, and impact resistance, all contributing to its exceptional durability and long lifespan.

Cement board’s exceptional performance is a result of its inherent properties and careful manufacturing. Let’s delve into the specific characteristics that contribute to its widespread use and long-term reliability in diverse climates and applications.

Fire Resistance

Cement boardsares inherently fire-resistant. Its non-combustible nature means it won’t contribute to the spread of flames in a fire. This characteristic is crucial for building safety and meets stringent fire codes in many regions. Independent testing has shown that cementboard rd can withstand extremely high temperatures for extended periods, and maintain its structural integrity even under intense heat. This high level of fire resistance makes it a superior choice compared to wood-based sheathing materials, which are highly flammable.

Moisture Resistance

Unlike many other sheathing materials, cement board offers excellent resistance to moisture damage. Its dense, non-porous structure prevents water absorption, minimizing the risk of rot, swelling, or mold growth. This is particularly beneficial in climates with high humidity or frequent rainfall. In coastal regions, for instance, cement board’s resistance to salt spray and moisture significantly extends its lifespan and reduces maintenance needs compared to wood or gypsum-based alternatives that are prone to degradation under such conditions.

Impact Resistance

Cement board possesses considerable impact resistance, meaning it can withstand significant blows without sustaining damage. This is a key advantage over other sheathing materials like plywood or OSB, which are more susceptible to dents, cracks, and punctures. This robustness is especially important in areas prone to high winds or where accidental impacts during construction are likely. The added strength provided by the reinforcing fibers further enhances its impact resistance.

Long-Term Durability and Maintenance

Cement board sheathing is known for its exceptionally long lifespan. With proper installation, it can endure decades without significant deterioration, even under harsh environmental conditions. Unlike wood sheathing which requires regular maintenance such as painting or sealing to protect against rot and insect infestation, cement board typically needs minimal maintenance. Its resistance to moisture, rot, and insect damage translates to lower long-term costs and reduced upkeep. Regular inspection for any signs of damage, such as cracks or loose fasteners, is recommended, but extensive maintenance is usually unnecessary.

Lifespan Comparison with Other Sheathing Materials

A direct comparison of lifespan highlights the cement board’s advantages. While the exact lifespan depends on the specific environmental conditions and installation quality, cement board consistently outperforms wood-based sheathing (plywood, OSB) and even gypsum sheathing in terms of longevity. In harsh coastal environments, for example, wood sheathing might require replacement within 10-15 years due to rot and insect damage, while cement board can easily last for 30 years or more with minimal maintenance. Similarly, in regions with frequent freeze-thaw cycles, cement board’s superior resistance to moisture damage provides a significant advantage over materials susceptible to cracking and degradation.

Environmental Considerations and Sustainability

Source: auslogics.com

Cement board sheathing, while a durable and versatile building material, carries environmental implications throughout its lifecycle, from raw material extraction to disposal. Understanding these impacts and exploring sustainable alternatives is crucial for responsible construction practices.

Cement production, a key component of cement board manufacturing, is an energy-intensive process that contributes significantly to greenhouse gas emissions, primarily carbon dioxide. The extraction and transportation of raw materials like cement, sand, and cellulose fibers also have environmental footprints. Disposal of cement board at the end of a building’s life adds to landfill volume and can contribute to the potential leaching of materials into the environment.

Manufacturing Impacts

The manufacturing process of cement board sheathing is responsible for a considerable portion of its overall environmental impact. Cement production, a core element, is a significant source of CO2 emissions due to the chemical reactions involved in the calcination of limestone. The energy consumption associated with this high-temperature process further contributes to the carbon footprint. Transportation of raw materials to manufacturing facilities and finished products to construction sites adds to the overall emissions. Furthermore, the production process may generate waste materials that require proper management to minimize environmental harm. Examples of this include dust and other byproducts that need to be carefully controlled and disposed of responsibly. The use of energy-efficient manufacturing techniques and the exploration of alternative, lower-carbon cement are important steps in mitigating these impacts.

Sustainable Alternatives and Practices

Several strategies can minimize the environmental impact associated with cement board sheathing. Choosing manufacturers committed to reducing their carbon footprint through initiatives like using alternative fuels or carbon capture technologies is a significant step. Specifying cement boards with higher recycled content can also reduce the demand for virgin materials. In some cases, exploring alternative sheathing materials, such as wood fiber panels or certain types of engineered wood products with lower embodied carbon, may offer a more sustainable choice depending on project specifics and regional availability. Proper waste management during construction and demolition, including recycling or repurposing of usable cement board, is also essential. For example, broken pieces could potentially be crushed and used as aggregate in other construction projects.

Recyclability and Reuse

Cement board sheathing’s recyclability is limited. While some manufacturers offer recycling programs, widespread infrastructure for recycling cement boards is not yet fully developed. However, reuse options exist. Salvaged cement boards from demolition projects, if undamaged, can be reused in applications like non-structural wall cladding or landscaping projects. Crushing the material into aggregate for use in other concrete mixtures is another possibility, though the extent of this practice is currently limited. Promoting the reuse of cement boards and improving recycling infrastructure is crucial to reducing its environmental impact at the end of its service life. Further research into the development of more readily recyclable cement board formulations could significantly enhance sustainability in the future.

Cost Analysis and Value Proposition

Source: sqlauthority.com

Choosing the right sheathing material involves careful consideration of both upfront costs and long-term value. A cement board, while initially more expensive than some alternatives, often proves a more economical choice over its lifespan due to its superior durability and reduced maintenance needs. Let’s break down the cost comparison and explore the long-term benefits.

Cement Board vs. Other Sheathing Materials: A Cost Comparison

This section details the cost differences between cement boards and common alternatives like plywood and OSB (Oriented Strand Board), factoring in material, installation, and potential repair costs. Generally, cement board’s higher initial cost is offset by its extended lifespan and reduced maintenance requirements.

| Material | Initial Cost (per sheet/sq ft – approximate) | Installation Cost (per sheet/sq ft – approximate) | Lifespan (years) | Maintenance Costs (estimated over lifespan) |

|---|---|---|---|---|

| Cement Board | $25-$40 | $5-$10 | 50+ | Low (minimal repainting/repair) |

| Plywood | $15-$25 | $3-$7 | 20-30 | Medium (potential water damage repair, repainting) |

| OSB | $10-$20 | $3-$7 | 15-25 | High (susceptible to water damage, more frequent repairs) |

*Note: Prices are approximate and vary based on location, supplier, and specific product characteristics. Installation costs also depend on labor rates and project complexity.*

Long-Term Value Proposition: Durability and Reduced Maintenance, Cement board structural sheathing

Cement board’s inherent strength and resistance to moisture, insects, and fire translate into significant long-term cost savings. Unlike plywood or OSB, which are prone to water damage and require more frequent repairs and replacements, cement board maintains its structural integrity for decades, minimizing the need for costly maintenance.

For example, a homeowner might spend an extra $5,000 upfront on cement board sheathing for a 2,000 sq ft house compared to using OSB. However, over 30 years the potential savings from avoiding repairs due to water damage, insect infestation, or fire could easily exceed that initial investment.

Return on Investment (ROI) Examples

Consider a commercial building project. Using cement board might add $20,000 to the initial construction cost compared to using less durable material. However, if the building’s lifespan is 50 years and the cement board prevents even one major repair costing $100,000 due to fire or water damage, the ROI is significantly positive. Similarly, in a coastal home prone to moisture damage, the longevity and resistance of cement board will quickly outweigh the initial higher cost compared to materials like plywood, which would require more frequent replacements.

Investing in durable materials like cement board translates to lower long-term costs and a better return on investment.

Common Issues and Troubleshooting

Cement board sheathing, while durable, can present some installation and performance challenges. Understanding these common issues and their solutions is crucial for ensuring a successful project and avoiding costly repairs down the line. Proper planning and careful execution are key to mitigating these problems.

Moisture Damage

Exposure to excessive moisture is a significant concern with cementboards. Prolonged contact with water can lead to weakening, cracking, and even the growth of mold and mildew. Preventing moisture intrusion is paramount.

- Problem: Water penetration during installation due to rain or improper sealing.

- Solution: Install cement board during dry weather. Use waterproof sealant around all joints and penetrations. Ensure proper flashing and caulking around windows and doors.

- Problem: Mold growth due to trapped moisture behind the sheathing.

- Solution: Ensure adequate ventilation behind the sheathing. Use vapor barriers where appropriate. Address any leaks promptly to prevent further damage.

Cracking and Breakage

Cement board, while strong, is susceptible to cracking under stress. Improper handling, fastening, or expansion and contraction can lead to fractures.

- Problem: Cracking during handling or installation due to dropping or excessive force.

- Solution: Handle the cement board carefully. Use appropriate lifting techniques and protective gear. Avoid dropping or excessive force during installation.

- Problem: Cracking due to improper fastening. Over-tightening fasteners can cause stress fractures.

- Solution: Use the correct fasteners and spacing recommended by the manufacturer. Avoid over-tightening fasteners. Pre-drill holes for larger screws to reduce the risk of cracking.

Fastener Issues

Using incorrect fasteners or improper fastening techniques can compromise the structural integrity of the sheathing and lead to problems.

- Problem: Fasteners that are too short or too long can lead to insufficient holding power or penetration into the framing.

- Solution: Use fasteners of the correct length and type recommended by the manufacturer and building codes. Ensure adequate penetration into the framing members.

- Problem: Improper fastener spacing can weaken the sheathing and reduce its load-bearing capacity.

- Solution: Maintain consistent fastener spacing as specified by the manufacturer’s instructions and building codes. This ensures uniform load distribution.

Improper Cutting and Handling

Cutting cement board improperly can lead to chipping and create weak points. This requires attention to detail and proper tools.

- Problem: Chipping or fracturing during cutting due to dull or inappropriate tools.

- Solution: Use a sharp, carbide-tipped saw specifically designed for cutting cement board. Score the board before cutting to minimize chipping.

- Problem: Dust inhalation during cutting.

- Solution: Wear a dust mask and eye protection during cutting. Use a wet saw to minimize dust generation.

Code Compliance and Regulations

Using cement board sheathing correctly is crucial for building a safe and structurally sound building. Ignoring building codes can lead to serious problems, from structural failures to legal issues. This section identifies key code considerations and how to ensure your project meets all necessary regulations.

Building codes, such as the International Building Code (IBC) and local amendments, specify requirements for exterior wall sheathing, including cement board. These codes dictate minimum thicknesses, fastener types and spacing, and installation methods to ensure the sheathing performs as intended, providing adequate structural support and protection against weather damage. Specific requirements will vary based on geographic location, building type, and intended use.

Relevant Building Codes and Standards

Compliance with building codes is paramount. The IBC, along with local amendments, provides the primary framework. These codes often reference standards from organizations like ASTM International, which establish testing procedures and performance criteria for building materials. For instance, ASTM C1185 covers the standard specification for fiber-cement siding, providing guidelines on material properties and quality control. Consult your local building department for the specific codes applicable to your project. They can provide detailed information on requirements and any local ordinances that may affect your project. Ignoring these requirements can result in project delays, costly revisions, or even the rejection of the project.

Ensuring Code Compliance During Design and Installation

Careful planning and meticulous execution are key to ensuring code compliance. Before starting construction, obtain all necessary permits and review the relevant building codes thoroughly. The design phase should incorporate the appropriate cement board thickness, fastener type, and spacing based on the design loads and local wind and seismic requirements. During installation, adhere strictly to the manufacturer’s instructions. Maintain consistent spacing of fasteners, ensuring proper penetration depth. Proper inspection throughout the installation process, by both the installer and a qualified inspector, is vital. Detailed documentation, including material certifications and installation records, is crucial for demonstrating compliance. This documentation may be required for permit approvals and insurance purposes.

Consequences of Non-Compliance

Non-compliance with building codes carries significant risks. Failure to meet code requirements can result in structural weaknesses, leading to potential collapse or damage during severe weather events. This poses a serious safety hazard to occupants and could lead to costly repairs or even legal action. Additionally, non-compliance can result in project delays due to necessary remediation work, increased insurance premiums due to higher risk, and even fines or legal penalties from building inspectors. In some cases, non-compliant work may require complete demolition and reconstruction. The financial and legal consequences can be substantial, emphasizing the importance of strict adherence to all applicable codes and regulations.

Ending Remarks: Cement Board Structural Sheathing

Cement board structural sheathing presents a compelling alternative for builders seeking durability, fire resistance, and moisture protection. By understanding its properties, applications, and installation best practices, you can leverage its strengths to create strong, resilient structures. Remember to always adhere to building codes and consider the long-term value proposition, balancing initial costs with reduced maintenance and extended lifespan. This guide provides a solid foundation for successful implementation.