Exterior Sheathing Panels A Comprehensive Guide

Exterior sheathing panels are the unsung heroes of any building’s exterior, forming the crucial structural layer beneath the siding. Understanding their different types, installation methods, and long-term performance is key to building a durable and energy-efficient home or structure. This guide dives into the specifics, covering everything from material selection to ensuring proper installation for optimal results.

We’ll explore the various materials available, including wood, plywood, OSB, fiber cement, and metal, comparing their pros and cons regarding cost, durability, and ease of installation. We’ll also cover proper installation techniques, addressing common pitfalls and emphasizing the importance of ventilation and moisture control. Finally, we’ll examine building codes and regulations, environmental impact considerations, and practical maintenance tips.

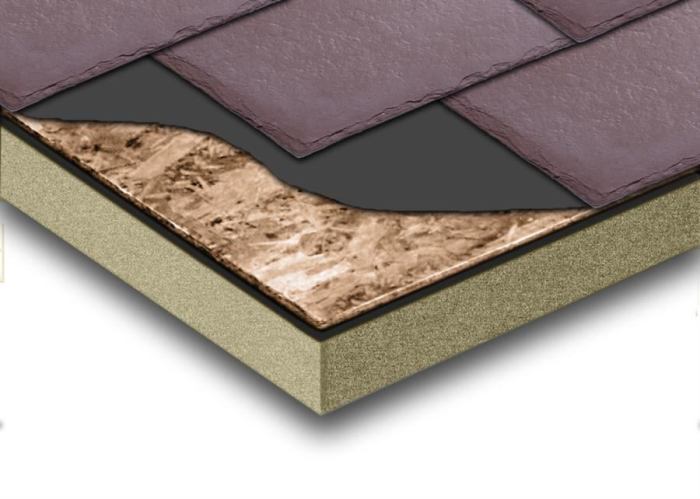

Types of Exterior Sheathing Panels

Source: windowsreport.com

Choosing the right exterior sheathing is crucial for a building’s structural integrity, weather resistance, and longevity. Different materials offer varying levels of performance, cost, and ease of installation. Understanding these differences is key to making an informed decision.

Wood Sheathing

Wood sheathing, typically in the form of planks or shiplap, is a traditional choice. It’s relatively inexpensive and easy to work with, making it a popular option for DIY projects. However, wood is susceptible to moisture damage, insect infestation, and fire. Common thicknesses range from ¾ inch to 1 inch, with standard lengths varying by manufacturer. Proper treatment with preservatives is essential to extend its lifespan.

Plywood Sheathing

Plywood sheathing offers improved strength and stability compared to solid wood planks due to its layered construction. It’s available in various grades, with higher grades offering better quality and durability. Plywood is relatively easy to cut and install, but it’s also susceptible to moisture damage if not properly protected. Standard thicknesses range from ½ inch to ¾ inch, with common panel sizes being 4′ x 8′. The cost is generally moderate.

Oriented Strand Board (OSB) Sheathing

OSB sheathing is an engineered wood product made from wood strands bonded together with resin. It’s generally less expensive than plywood and offers comparable strength. OSB is also susceptible to moisture damage and can be more prone to edge damage during handling and installation. Thicknesses and sizes are similar to plywood, ranging from ½ inch to ¾ inch and commonly 4′ x 8′.

Fiber Cement Sheathing

Fiber cement sheathing is a non-combustible material made from a mixture of cement, cellulose fibers, and other additives. It offers excellent durability, fire resistance, and moisture resistance. However, it’s more expensive than wood-based options and can be more challenging to cut and install, often requiring specialized tools. Common thicknesses range from ½ inch to ⅝ inch, with typical panel sizes similar to plywood and OSB.

Metal Sheathing

Metal sheathing, typically made of steel or aluminum, provides exceptional durability and fire resistance. It’s resistant to rot, insects, and moisture damage. However, it’s more expensive than other options and can be more challenging to install, requiring specialized tools and fasteners. It’s also susceptible to dents and scratches. Thickness and sizes vary greatly depending on the specific product and intended application.

Comparison of Exterior Sheathing Panel Materials

| Material | Cost (Relative) | Durability | Fire Resistance |

|---|---|---|---|

| Wood | Low | Moderate (Susceptible to rot and insects) | Low |

| Plywood | Medium | Good (Requires proper protection from moisture) | Moderate |

| OSB | Low to Medium | Good (Requires proper protection from moisture) | Moderate |

| Fiber Cement | High | Excellent (Resistant to rot, insects, and moisture) | Excellent |

| Metal | High | Excellent (Resistant to rot, insects, and moisture) | Excellent |

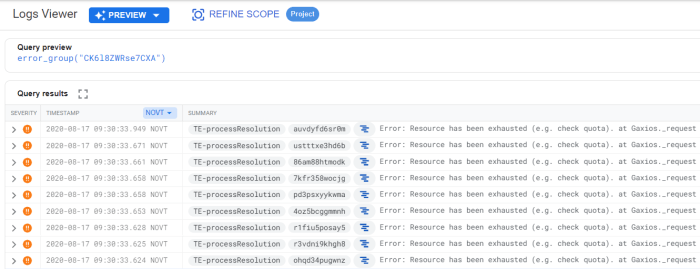

Installation Methods for Exterior Sheathing Panels

Source: sstatic.net

Getting exterior sheathing installed correctly is crucial for a building’s structural integrity and weather resistance. Proper installation involves understanding the type of sheathing, the wall framing, and following best practices for nailing, ventilation, and moisture management. This section will guide you through the process.

Nailing Patterns and Fastener Selection

Choosing the right nails and applying them correctly is paramount to ensure the sheathing is securely attached and resists wind uplift and other forces. The type of nail, its length, and the spacing between nails all depend on the sheathing material, the framing, and local building codes. Generally, longer nails are needed for thicker sheathing and for areas with higher wind loads.

- Nail Type: Use galvanized nails specifically designed for exterior sheathing to resist corrosion. Common options include common nails, ring-shank nails (for better holding power), and spiral nails (for added resistance to pullout).

- Nail Length: The nail should penetrate the framing member by at least 1 inch. Consult the sheathing manufacturer’s instructions for recommended nail lengths.

- Nail Spacing: Spacing varies depending on the sheathing material and the framing. Typically, nails are spaced 6 inches apart along the edges and 8-12 inches apart in the field. Again, always refer to the manufacturer’s instructions and local building codes.

- Nailing Pattern: Panels should be nailed to each framing member. Common patterns include edge nailing and field nailing. Edge nailing uses a closer spacing along the edges to prevent lifting, while field nailing secures the center of the panel. Always follow the recommended pattern for your specific sheathing.

Sheathing Installation on Wood Framing

Installing sheathing on wood framing is a relatively straightforward process. The key is to ensure the framing is properly prepared and that the sheathing is installed correctly.

- Prepare the Framing: Ensure the framing is plumb, square, and true. Any irregularities can lead to problems with the sheathing installation.

- Install the First Panel: Start at a corner and align the panel with the framing members. Nail the panel according to the manufacturer’s recommendations and the nailing pattern.

- Install Subsequent Panels: Stagger the joints between panels to create a strong, interlocking system. Ensure panels are butted tightly together. Use appropriate shims to maintain proper spacing and alignment.

- Cut and Fit Panels: Use a circular saw or other suitable cutting tool to cut panels around windows and doors. Always make sure to leave sufficient space for expansion and contraction.

- Finishing: Once all panels are installed, inspect for any gaps or loose nails and address them as needed.

Sheathing Installation on Metal Studs

Metal stud framing requires slightly different techniques due to the material’s properties. Self-tapping screws are generally used instead of nails.

- Fastener Selection: Use self-drilling or self-tapping screws designed for metal framing and exterior sheathing. The screws should be long enough to provide adequate penetration.

- Screw Spacing and Pattern: Follow the manufacturer’s recommendations for screw spacing and pattern. Spacing will likely be closer than with wood framing due to the different material properties.

- Special Considerations: Metal studs can conduct heat and cold more efficiently than wood. Consider using appropriate insulation and vapor barriers to minimize energy loss.

Ventilation and Moisture Management

Proper ventilation and moisture management are crucial to prevent mold, rot, and other problems. This involves ensuring adequate air circulation behind the sheathing and using appropriate vapor barriers to prevent moisture from entering the wall cavity.

Moisture can significantly damage sheathing and compromise the building’s structural integrity. Effective ventilation helps to dry out any moisture that may accumulate. A properly installed vapor barrier prevents moisture from entering the wall cavity from the interior of the building.

Cutting and Fitting Sheathing Around Openings

Precise cutting and fitting are necessary for a professional-looking and weather-tight installation around windows and doors.

- Measure and Mark: Carefully measure and mark the sheathing panel to ensure accurate cuts around the openings.

- Cut the Panel: Use a circular saw or jigsaw to make the cuts. Make sure to use a sharp blade to avoid splintering or chipping.

- Fit the Panel: Carefully fit the cut panel into place. Ensure it’s flush with the framing and that there are no gaps.

- Secure the Panel: Nail or screw the panel securely in place, following the manufacturer’s recommendations.

- Caulk and Seal: Apply a suitable caulk or sealant around the edges of the panel to create a weather-tight seal.

Sheathing Panel Performance and Durability

Source: techcaption.com

Exterior sheathing panels are crucial for a building’s structural integrity and weather resistance. Their long-term performance depends on several factors, from the initial quality of the material to the skill of the installer and the environmental conditions they face. Understanding these factors is key to ensuring a durable and long-lasting building envelope.

Factors Affecting Long-Term Performance

Several factors significantly influence the longevity of exterior sheathing panels. Weather exposure is a major one; prolonged exposure to sun, rain, wind, and temperature fluctuations can cause cracking, warping, and deterioration of the material. Different materials react differently to these elements; for example, wood sheathing is susceptible to rot and insect infestation if not properly treated, while certain engineered wood products offer better resistance but can still be affected by moisture. Insect infestation, particularly termites and carpenter ants, can cause significant structural damage, compromising the integrity of the sheathing and the entire building. Finally, the initial quality of the panels themselves plays a role; using low-grade or damaged materials will inevitably lead to reduced performance.

Problems Associated with Improper Installation

Improper installation of exterior sheathing panels can lead to a cascade of problems, severely impacting the building’s performance and lifespan. Water damage is a primary concern; gaps, overlaps, or improper sealing around windows and doors allow water penetration, leading to rot, mold growth, and structural weakening. This can also cause damage to interior finishes. Furthermore, improper fastening can result in structural failure, especially during high winds or seismic activity. The panels might not be adequately secured, leading to movement and damage. Finally, incorrect installation can compromise the building’s energy efficiency, resulting in higher heating and cooling costs.

Best Practices for Maintaining and Protecting Exterior Sheathing Panels

Regular inspection is crucial for early detection of problems. Look for signs of water damage, insect infestation, cracking, or loose fasteners. Proper sealing around windows, doors, and other penetrations prevents water intrusion. Regular cleaning removes dirt and debris that can accelerate deterioration. For wood sheathing, periodic treatment with a water-repellent preservative helps prevent rot and insect damage. Addressing any damage promptly is key to preventing more extensive and costly repairs later. Proper ventilation behind the sheathing is also important to prevent moisture buildup.

Visual Representation of Improper Installation Impact

Imagine a section of sheathing with gaps between the panels. Rainwater penetrates these gaps, soaking the underlying sheathing and framing. This moisture leads to rot and mold growth, weakening the wood and causing it to swell. In a separate area, imagine fasteners spaced too far apart. Under wind load, the panels flex excessively, leading to cracks and potential failure. The illustration would show water seeping through the gaps, staining and rotting the wood. In the area with insufficient fastening, arrows would show the direction of the wind load, and the panels would be depicted as bowing or cracking. This visual contrast would clearly show how proper installation ensures watertightness and structural stability, while improper installation leads to rapid deterioration and potential structural failure.

Building Codes and Regulations for Exterior Sheathing

Source: imgur.com

Navigating the world of exterior sheathing can feel like deciphering a secret code, but understanding building codes is crucial for a safe and durable structure. These regulations aren’t arbitrary; they’re designed to protect you and your investment, ensuring your building can withstand various environmental pressures and potential hazards. This section will clarify the key aspects of building codes as they relate to exterior sheathing.

Building codes regarding exterior sheathing vary significantly depending on location, primarily due to differences in climate and the types of natural disasters a region experiences. For example, areas prone to hurricanes will have stricter requirements for wind resistance than areas with milder weather. Understanding these variations is critical for selecting the right sheathing and ensuring proper installation.

Impact of Local Climate Conditions on Sheathing Requirements

Climate plays a dominant role in determining the type and installation of exterior sheathing. High winds necessitate sheathing with greater strength and secure fastening, while areas with heavy snowfall require sheathing that can handle significant weight loads without structural failure. Similarly, regions with high humidity need sheathing resistant to moisture damage and mold growth. Ignoring these climatic factors can lead to costly repairs and compromise the structural integrity of the building.

Selecting Appropriate Sheathing for Different Building Applications

Residential and commercial buildings have different requirements for exterior sheathing. Residential construction often prioritizes cost-effectiveness while meeting basic code requirements, whereas commercial buildings might demand higher performance standards to meet stricter building codes and potentially longer lifespans. The size and complexity of the building also influence sheathing choices. Larger structures may require more robust sheathing to manage greater wind loads and overall structural stress.

Examples of Building Code Requirements for Sheathing Installation in Different Regions

The specifics of building codes are complex and vary widely. However, here are some illustrative examples:

- International Building Code (IBC): The IBC provides a widely adopted baseline, but individual jurisdictions often amend it to reflect local conditions. For instance, coastal regions might mandate higher wind-load resistance ratings for sheathing than inland areas. Specific requirements regarding fastener type, spacing, and edge distances are detailed within the code.

- Southern Building Code (SBC): The SBC often addresses issues specific to the southern United States, such as hurricane preparedness. This might include requirements for impact-resistant sheathing and stricter guidelines for water-resistance. These codes reflect the increased likelihood of high winds and heavy rainfall.

- California Building Code (CBC): California’s unique climate and susceptibility to earthquakes result in building codes that emphasize seismic resistance. Sheathing requirements may include specifications for shear strength and the use of specific fastening methods to ensure structural stability during seismic events.

Note that these are simplified examples; always consult the specific building codes for your region and project before starting construction. Ignoring these regulations can lead to significant penalties and potential structural problems. It is highly recommended to work with a qualified building professional familiar with your local codes.

Environmental Impact of Exterior Sheathing Panels

Source: sstatic.net

Choosing exterior sheathing involves more than just structural integrity; it also impacts the environment. The manufacturing, transportation, and eventual disposal of these panels contribute to our carbon footprint and resource depletion. Understanding the environmental consequences of different materials is crucial for making responsible building choices.

The environmental impact of exterior sheathing varies significantly depending on the material used. Factors like embodied carbon (the carbon emissions associated with a product’s entire lifecycle), recyclability, and the sourcing of raw materials all play a significant role. Sustainable options are increasingly available, offering builders a chance to minimize their environmental footprint.

Embodied Carbon in Sheathing Materials, Exterior sheathing panels

Embodied carbon is a key indicator of a material’s environmental impact. It considers the greenhouse gas emissions released during the extraction of raw materials, manufacturing, transportation, and even the eventual demolition and disposal. Materials with high embodied carbon contribute more to climate change than those with lower embodied carbon footprints. For example, the production of cement-based products like fiber cement sheathing has a higher embodied carbon compared to wood sheathing from sustainably managed forests. Steel sheathing also carries a substantial embodied carbon footprint due to the energy-intensive steel manufacturing process.

Recyclability and End-of-Life Management

The recyclability of sheathing materials is another critical environmental factor. Some materials, like certain types of wood sheathing, can be recycled or repurposed, reducing landfill waste. However, others, like some OSB (Oriented Strand Board) and fiber cement products, have limited recyclability options. Proper disposal methods, such as recycling or responsible disposal in landfills, are crucial to minimize the environmental impact at the end of the sheathing’s lifespan. Understanding the recycling options available in your area for each sheathing type is important for responsible construction practices.

Sustainable Sheathing Options and Alternatives

Several sustainable sheathing options are emerging, aiming to reduce the environmental impact of construction. These include:

- Recycled content sheathing: Sheathing made partially or entirely from recycled materials reduces the demand for virgin resources and minimizes landfill waste.

- Rapidly renewable materials: Sheathing made from rapidly renewable resources, such as bamboo or certain fast-growing tree species, reduces pressure on old-growth forests.

- FSC-certified wood sheathing: Choosing sheathing from forests certified by the Forest Stewardship Council (FSC) ensures that the wood comes from responsibly managed forests that prioritize environmental sustainability.

These sustainable alternatives often come with a higher initial cost, but their long-term environmental benefits and potential for reduced operational costs can outweigh the initial investment.

Responsible Sourcing and Disposal

Responsible sourcing ensures that the materials used in construction are obtained ethically and sustainably. This includes supporting suppliers who adhere to strict environmental and social standards. Similarly, responsible disposal involves properly recycling or disposing of sheathing materials at the end of their lifespan, reducing landfill waste and minimizing environmental harm. Proper disposal reduces the risk of harmful substances leaching into the environment.

Comparison of Environmental Impacts

| Sheathing Material | Embodied Carbon (kg CO2e/m²) | Recyclability | Sustainable Sourcing Options |

|---|---|---|---|

| Wood (SPF) | Variable, depends on forestry practices; generally lower than other options | Potentially recyclable or repurposable | FSC certification |

| OSB | Moderate | Limited | FSC certification, recycled content options available |

| Fiber Cement | High due to cement production | Limited | Some manufacturers offer recycled content options |

| Steel | High due to steel production | Recyclable | Recycled steel content options |

| Bamboo | Generally low | Potentially recyclable or repurposable | Sustainable harvesting practices |

Note: The embodied carbon values are estimates and can vary significantly depending on factors like manufacturing processes, transportation distances, and specific product formulations. Recyclability can also vary based on local infrastructure and recycling programs.

End of Discussion

Source: insided.com

Building a strong, lasting structure depends heavily on the correct selection and installation of exterior sheathing panels. By carefully considering material properties, following best practices for installation, and adhering to building codes, you can ensure your building’s longevity and structural integrity. Remember, understanding the nuances of sheathing – from material choices to long-term maintenance – is vital for creating a robust and resilient building envelope. This guide provided a foundation; always consult local building codes and professionals for specific project needs.